Metal Separators

MAGNETIC ROD

Magnetic Rods are extremely efficient at removing ferrous and para-magnetic contamination down to sub micron in size from free flowing products including powders & liquids. Rods can be incorporated into machineries with minimal amount of redesign and also offering flexibility. Each rod is tapped with a standard M8 thread at both ends for ease of installation, or alternatively without threaded details or with studs, which can be specified during order placement.

KEY FEATURES:

- Rods are constructed with High Intensity Rare Earth NdFeB magnet.

- Remove sub micron sized ferrous and para-magnetic contaminants

- Easy to clean, simple to use, enables flexible design

- Can be configured and installed at any process area.

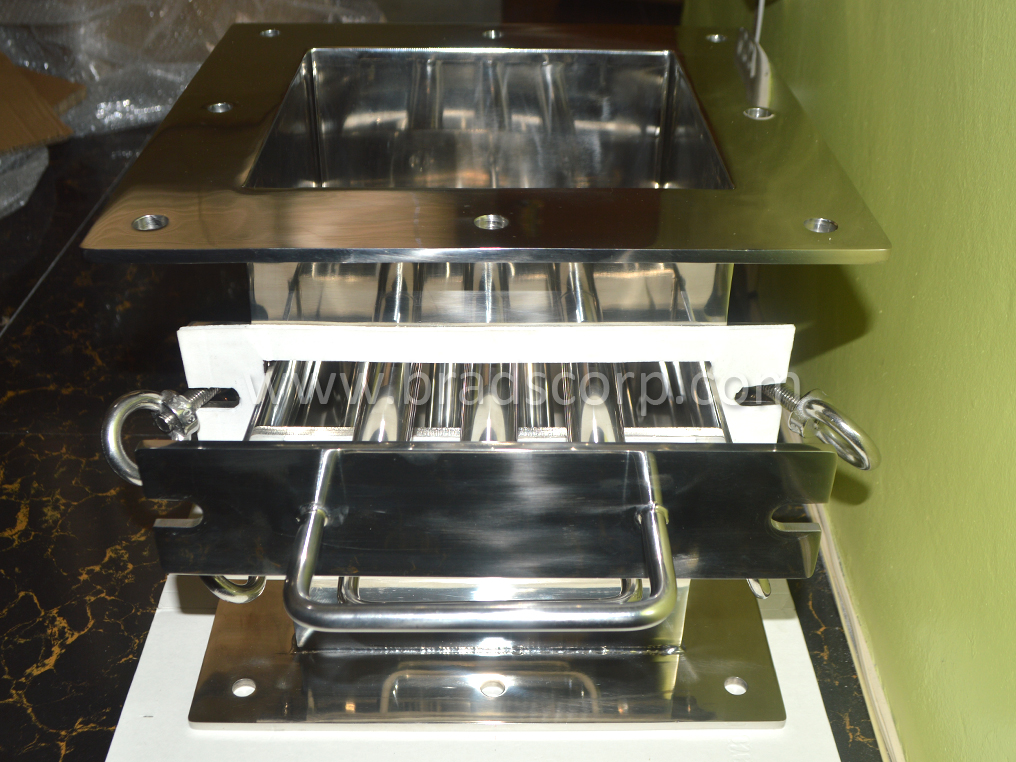

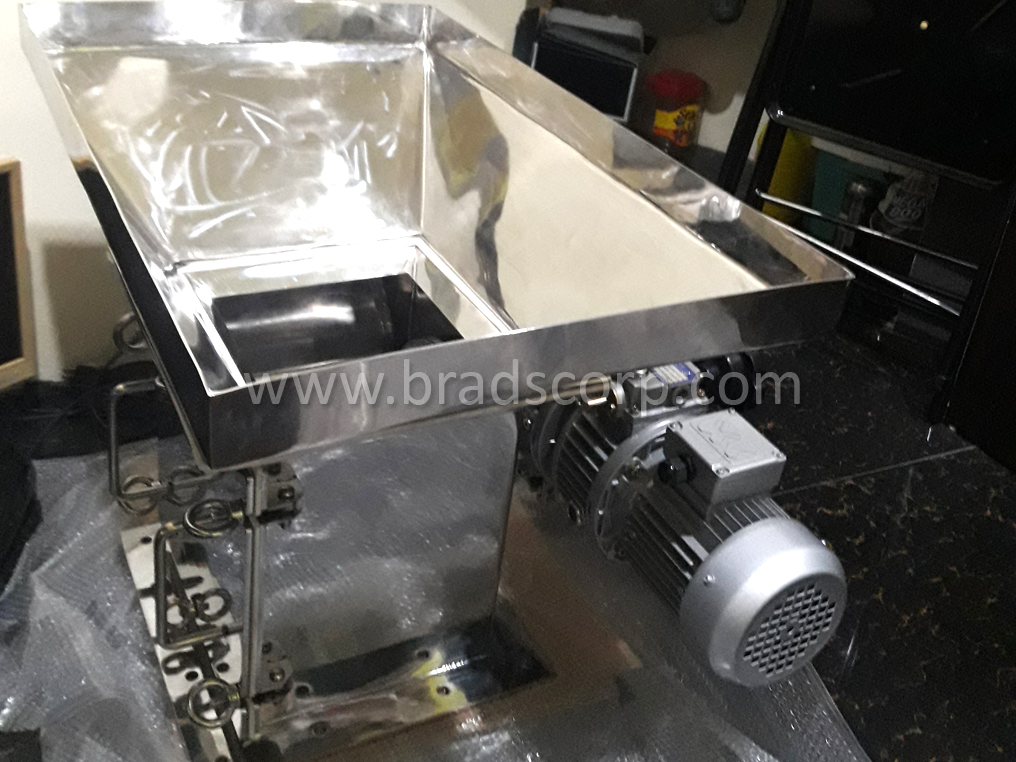

HOPPER MAGNET / MAGNETIC GRATE

Hopper Magnets Metal Separators are very versatile and can be utilized in most powder, granulate and liquid applications for the removal of ferrous and para-magnetic contamination down to sub micron in size. These units can be fabricated to any size and with any number of layers and rods to meet most application requirements. Due to the grids low profile side frame, these units can be installed into existing chute or machinery where height is a restriction.

KEY FEATURES:

- Utilizes High Intensity Rare Earth NdFeB magnets

- Removes sub-micron ferrous & paramagnetic contamination from dry powders & granular materials

- Easy to clean, maintains product flow, high collection capacity, food-grade polish

MAGNETIC LIQUID FILTER

The Magnetic Liquid Filter has been designed to operate in pressurized transfer lines to provide protection against ferrous and paramagnetic contamination. The unit comprises of a vessel, magnetic lid assembly and band clamp, which secures the unit together. The filter works in all types of liquid products such as Chocolate, Molasses, Jam, Syrup, Juice, Sauce, Paste, Soup, Pickles, Spreads, and Beverages etc.

KEY FEATURES:

- Magnetic Lid is built with High Intensity Rare Earth NdFeB magnet

- Removes sub micron sized ferrous and paramagnetic contaminants

- Can be installed at any angle from vertical to horizontal

- Can be utilized in any line that processes liquids at all viscosity levels

PLATE MAGNET

The Plate Magnet have been designed to operate in arduous conditions and where contamination size is relatively small-medium e.g. filings, nuts, bolts etc. It can be incorporated into any form of angled chute section. A common installation location is end product outlet points prior to bagging. Plate Magnets are versatile and can be utilized in various processes. These units are usually installed above transfer conveyors, chutes and vibratory feeders to attract ‘tramp’ metal contamination and any loose machine part that has fallen off during the manufacturing or packaging stages. Magnetism is only present on one face ensuring that no surrounding sensitive process machinery is affected.

KEY FEATURES:

- The unit is constructed with High Intensity Rare Earth NdFeB type magnet

- Removes tramp metal contamination even when trapped underneath the product

- Flexible design, can be configured into different dimensions and process installations

- Allows water and chemical clean down due to the unit’s full Stainless Steel construction

- Comes with testing certificates to guarantee Gauss value upon delivery valid for one (1) year